When it comes to heavy vehicle repairs, safety isn’t just best practice—it’s the law. OSHA (Occupational Safety and Health Administration) sets clear requirements for workplace safety, including dump truck maintenance. Mechanics working on dump trucks face high-risk conditions, especially when the truck bed is raised. Without proper precautions, a single equipment failure can result in serious injury or even death. That’s why OSHA emphasizes safe work procedures, equipment inspections, and the use of secure support devices.

For dump truck maintenance, one of the most critical components for compliance and safety is the use of reliable dump bed support equipment. BedLock Safety Products LLC manufactures truck bed locks that not only help mechanics work more safely but also align with OSHA’s safety standards. Let’s break down what you need to know about OSHA guidelines and how BedLock’s solutions fit in.

Understanding OSHA’s Requirements for Dump Truck Maintenance

OSHA regulations for heavy vehicle maintenance focus on preventing accidental lowering of elevated components, controlling hazardous energy, and ensuring equipment stability. When working under a raised dump bed, OSHA requires that employers:

- Provide positive supportsto prevent accidental lowering.

- Ensure supports are strong enoughto handle the weight and potential shock load of the bed.

- Train workersin proper installation and use of support equipment.

- Inspect support devicesregularly for wear, damage, or defects.

Improvised supports—like wood blocks, makeshift metal props, or unsecured stands—do not meet OSHA’s requirements. They can shift, fail, or collapse unexpectedly, creating catastrophic hazards.

Why OSHA Emphasizes Positive Dump Bed Supports

OSHA’s guidelines are based on one reality: gravity is unforgiving. Dump truck beds are heavy, and hydraulic systems are not fail-proof. If a hydraulic line bursts, a control valve malfunctions, or someone accidentally activates the system, the bed can drop instantly. Without a positive mechanical lock in place, anyone beneath the bed is in danger.

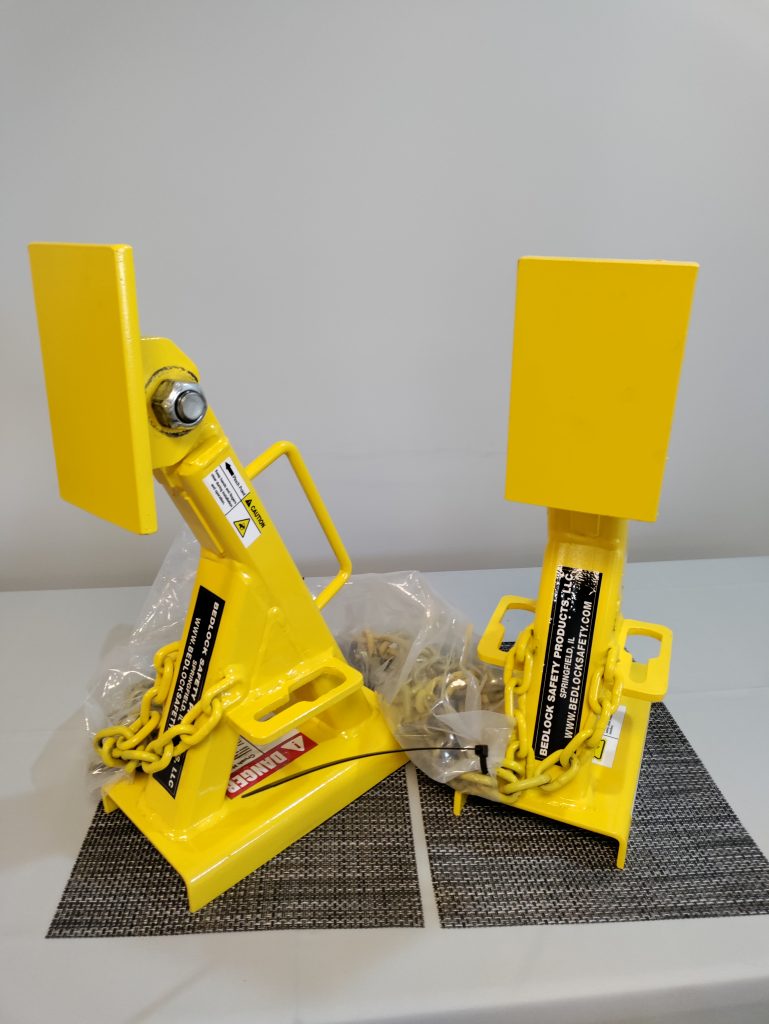

BedLock Safety Products LLC specializes in manufacturing dump truck safety equipment designed specifically to meet OSHA’s requirements for strong, stable, and reliable bed support. Unlike makeshift props, BedLock devices are purpose-built, tested, and engineered to handle the demands of real-world repairs.

How BedLock Truck Bed Locks Align with OSHA Standards

BedLock’s dump bed locks provide a physical barrier that prevents the bed from lowering unexpectedly. Here’s how they help mechanics meet OSHA safety guidelines:

- Positive Mechanical Support– BedLock locks into place, physically blocking the bed from descending, which is exactly what OSHA’s “positive supports” requirement demands.

- Strength and Stability– Each unit is engineered from high-strength steel, tested to support the massive weight of commercial dump beds.

- Ease of Use– Mechanics can install BedLock devices quickly, reducing downtime while still maintaining OSHA compliance.

- Inspection-Friendly Design– The straightforward structure makes it easy to spot wear or damage during required inspections.

- Universal Fit Options– With multiple models available, BedLock can be matched to different truck sizes and configurations, ensuring the right fit for the job.

Common OSHA Violations in Dump Truck Maintenance

Even well-intentioned shops can fall short of OSHA compliance if they overlook safety details. Some frequent violations include:

- Using Improvised Props– Wooden blocks, loose metal bars, or random objects are unstable and non-compliant.

- Failing to Train Staff– OSHA requires training on safe support use and hazard recognition.

- Skipping Inspections– Supports must be checked before each use and regularly maintained.

- Working Without Lockout/Tagout– OSHA requires control of hazardous energy during maintenance to prevent accidental activation.

BedLock products help eliminate these risks by providing equipment that’s OSHA-compliant by design and easy to use correctly every time.

Meeting OSHA’s Training and Inspection Requirements

OSHA compliance isn’t just about having the right equipment—it’s also about using it correctly. BedLock supports this by offering simple, clear installation steps that make training straightforward. Mechanics learn to:

- Position the truck bed at the correct height.

- Place the BedLock unit securely in position.

- Verify that it is locked and stable before working underneath.

- Inspect the device for cracks, rust, or wear before and after each use.

This ease of training helps shops meet OSHA’s requirement for safety instruction without overcomplicating the process.

The Long-Term Benefits of OSHA Compliance

Complying with OSHA standards doesn’t just prevent fines—it protects lives, reduces liability, and boosts productivity. With proper equipment like BedLock truck bed locks, shops experience:

- Fewer Workplace Injuries– Reducing risk means fewer accidents and workers’ compensation claims.

- Higher Employee Confidence– Mechanics can focus on repairs knowing they’re protected.

- Better Reputation– Compliance demonstrates professionalism and responsibility to clients and regulatory agencies.

- Cost Savings– Avoiding fines, legal costs, and lost workdays keeps operations profitable.

BedLock Models for OSHA-Compliant Shops

BedLock Safety Products LLC offers several models to meet different dump truck sizes and configurations:

- BL-450A/B– Ideal for lighter-duty applications.

- BL-600A/B– Designed for medium-duty trucks.

- BL-700A/B– 7-inch base for added stability in heavy-duty work.

- BL-800A/B– 8-inch base for maximum strength in large fleets.

By choosing the right model, shop owners ensure both OSHA compliance and optimal safety for their team.

Why Improvised Solutions Don’t Measure Up

It’s tempting for some shops to save money by creating their own dump bed props. However, OSHA’s guidelines are clear: only supports designed and rated for the load can be used. Improvised supports:

- Are rarely tested for weight capacity.

- Can shift or break under stress.

- May not fit securely, creating instability.

- Will not pass OSHA inspections.

BedLock products are manufactured to meet these critical safety standards, ensuring that your shop won’t fail a compliance check due to unsafe equipment.

Safety and Compliance Go Hand-in-Hand

In heavy vehicle maintenance, safety is not optional—and OSHA’s rules reflect that reality. By integrating BedLock’s dump bed safety support systems into your shop’s procedures, you’re not just ticking a compliance box. You’re building a safer, more efficient, and more professional operation.

OSHA compliance isn’t just about avoiding fines—it’s about saving lives.

Upgrade your shop’s safety standards today with OSHA-compliant dump truck safety equipment from BedLock Safety Products LLC. Call them or visit their website to find the right truck bed lock for your fleet.

Author’s Bio

James A. is a seasoned safety equipment specialist with a passion for promoting workplace safety. When not writing about truck maintenance, he enjoys woodworking, hiking, and classic car restoration.

You must be logged in to post a comment.